Product Development

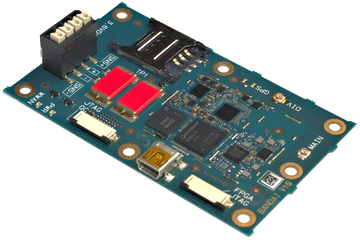

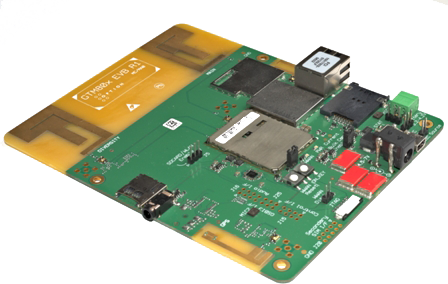

Our decades of RF, analog and digital communications experience can help speed you through every stage of wireless product development. Our system architects, with access to high-end PCB design tools and databases, can quickly review your product plans to determine if your goals are achievable within a given technology and form factor. Option is deeply experienced in 2G, 3G, 4G, WiFi, GPS and ZigBee – and we specialize in the integration of multiple technologies on a single device. We help prevent developmental “dead ends” and multiple design cycles that can lead to cost overruns.

Option Engineering Services can help you avoid these common pitfalls. For more than 25 years, we’ve helped coordinate the manufacturing process numerous global organizations. From proactive strategic consulting, production-friendly product design and engineering to hands-on production organization. Option has the experience and resources – including an extensive database of information gathered during the production of numerous devices – to help save time and money in the manufacturing process. With Option Engineering Services, we’ll help get your product to market in the fastest, most efficient manner possible.

As a company that is deeply committed to adding value to our clients’ projects, Option will always seek the fastest, most efficient and effective methods to reach your objectives. Our consulting services include:

- System Level Design

- Schematic Entry

- Layout (RF, High Speed, Signal Integrity and EMC our specialties)

- Test and Debugging (Plus Automated Testing to validate designs)

- Thermal Design

- Design Optimization for High Volume Manufacturing

RF/EMC consulting

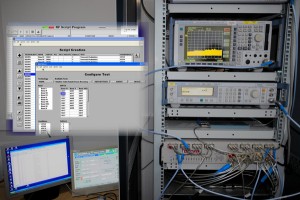

OptionLab is our in-house testing center. Equipped with a variety of the latest testing equipment and staffed by numerous engineers with years of experience – OptionLab is able to pinpoint RF and interference issues effectively and proactively, so we can advise your company on how to eliminate problems as early as possible in the development process.

With our years of experience, we have substantial expertise in the following areas:

- Rules/Regulatory Review

- Mechanical Stack-Up Review

- Schematic Review

- PCB Layout Review

- Signal Integrity Check

- Product Testing

- Compact RF Chamber Testing

Test automation & Pre-compliance testing

Using OptionLab’s communications testing equipment and test automation software, we can assist with compliance testing for WiFi/Bluetooth, 2G, 3G (UMTS/CDMA), and 4G (LTE).

OptionLab can also handle complex RF test set-ups for design, conformance and benchmark testing to help validate products, certify them or benchmark its performance against competitors.

Our test automation and pre-compliance testing services include:

- Standardized testing for 3GPP, IEEE and numerous other benchmarks

- Throughput performance testing (conducted and radiated test set ups)

- Load pull measurements for amplifiers

- Customized RF parametric testing

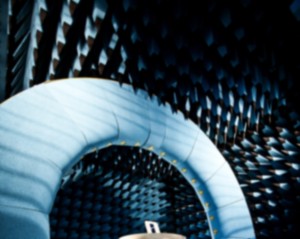

Antenna design and measurement

For best performance, antenna integration should be considered as early as possible in the product design process. Option knows that the market requirements mean there is more to this kind of work than simply buying an off the shelf component and adding it to your product. Since embedded antennas interact with the device as a whole, early involvement of a properly qualified and experienced engineer can help avoid costly and time-consuming revisions later on, and Option is here to help.

Between our experienced staff of highly qualified engineers, plus the resources of OptionLab, which includes a dedicated set of in-house antenna chambers for prototype measurement and optimization, your products will offer the performance, quality and overall integrity necessary to stand out in today’s crowded marketplace. Option can help define performance targets, ensure compliance with regulatory agencies and network operators, and provide overall design expertise during the development of your products. With our team and the resources of OptionLab – products will get to market faster and perform better than ones developed by newcomers to the wireless industry.

Services offered include:

- Stamped metal and PCB antenna design

- Prototyping for 2G/3G/4G, WLAN, GPS, Bluetooth, etc.

- Fast antenna measurements in an anechoic or reverberation chamber (700MHz-6GHz) antenna efficiency, gain, radiation patterns can all be evaluated

- Antenna matching

- OTA performance measurements (TIS/TRP)

- Diversity gain and MIMO performance measurements

- SAR measurements

Hardware Validation, Environmental Compliance & Reliability Testing

Taking “Design for Manufacturability” (DFM) measures in to account during the design phase will relax the strains during early production stages. It is by far much easier to ramp up production when necessary measures have been taken to align the design with the manufacturing process.

The Validation and Compliance program include:

- DFX reviews.

- Validation plan composition, based on industry standards.

- Thermal evaluation through infrared inspection and/or thermocouple measurements.

- Automated current consumption logging under various conditions.

- Signal integrity verification & USB compliance testing.

- Mechanical reliability & cosmetic quality verification.

- Vibration testing.

- Environmental testing for both temperature and humidity. Thermal shock testing.

Mechanical Design

It is hard to make an impression by introducing a product without a solid mechanical buildup. No matter how good your electrical performance would be, having a comprehensive overview of your mechanical buildup is a necessary aspect to increasing your chance of success. Our mechanical experts can support you with the mechanical stack-up of your electronic design, advice you in the selection and the design of your (electro-) mechanical parts. This will allow you to avoid common mistakes in early stages. It could be as simple as a clearance issue or incompatible parts caused by mechanical tolerances.

Our mechanical department offers:

- 3D modeling of metal/plastic parts

- Interference check mechanical assembly

- Design heat sinks, cooling fins

- Design of shielding cans

- Design of antennas

- Design of test fixtures for production testing